How transparency and circularity come together

Sustainable construction requires well-founded choices. Not only in design and execution, but also in material use. Increasingly, building projects are assessed on the basis of Environmental Product Declarations (EPDs): standardised documents that provide insight into the environmental impact of a product across its entire life cycle.

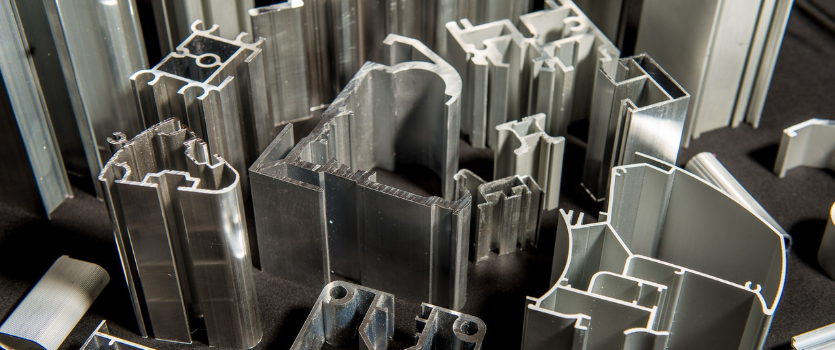

For aluminium extrusion profiles, this means transparency in raw material use, energy consumption, emissions, transport, processing, and end-of-life scenarios. And it is precisely here that aluminium as a material stands out.

What is an EPD?

An EPD is an objective, standardised declaration of a product’s environmental performance. In Europe, they are prepared in accordance with the EN 15804 standard and are often included in national databases such as the Dutch National Environmental Database (NMD). For construction professionals, EPDs are essential for:

Comparing materials based on CO₂ impact and circularity

Substantiating sustainability objectives in tenders

Meeting certification requirements such as BREEAM, LEED, and DGNB

Aluminium and EPDs: Why is it relevant?

Aluminium performs well in EPDs when produced with attention to origin and energy use. The environmental impact of aluminium extrusion profiles depends strongly on:

Billet type: primary aluminium has a higher CO₂ footprint than billets made from recycled content.

Energy consumption during production: when aluminium is produced using renewable energy sources, the environmental impact decreases significantly.

Formability and machinability: aluminium can be shaped and processed efficiently, reducing material waste and making production more efficient — directly lowering environmental impact.

Practical application in construction: thanks to its low weight, aluminium is easier and more economical to transport, while installation on site is faster and simpler, leading to fewer emissions and shorter build times.

Durability and circularity: aluminium is robust, low-maintenance, and fully recyclable without loss of quality. This keeps the material in circulation for longer and significantly reduces total environmental impact over its life cycle.

By optimising these factors, aluminium profiles can demonstrate a measurably low environmental impact and contribute directly to the sustainability ambitions of construction projects.

What does this mean for designers and builders?

For technical decision-makers, EPD transparency ensures that material choices are not only aesthetically or structurally justified, but also ecologically responsible. Aluminium offers:

Measurable performance: through recognised EPDs and LCA data*

Design flexibility: thanks to extrusion techniques and processing options

Circular potential: through reuse and closed material loops

*Life Cycle Assessment Data