Aluminium truly reveals itself when you hold it in your hands

Aluminium, a tool for builders, designers and engineers

A profile still warm from the press, a cross-section that shows exactly where the forces run, a prototype you can turn, test and refine. In real-world construction, material choice isn’t made on paper but through solutions that perform under time pressure, weather exposure, tolerances and installation demands. That’s where extruded aluminium proves itself - not as a concept, but as a tool for builders, designers and engineers.

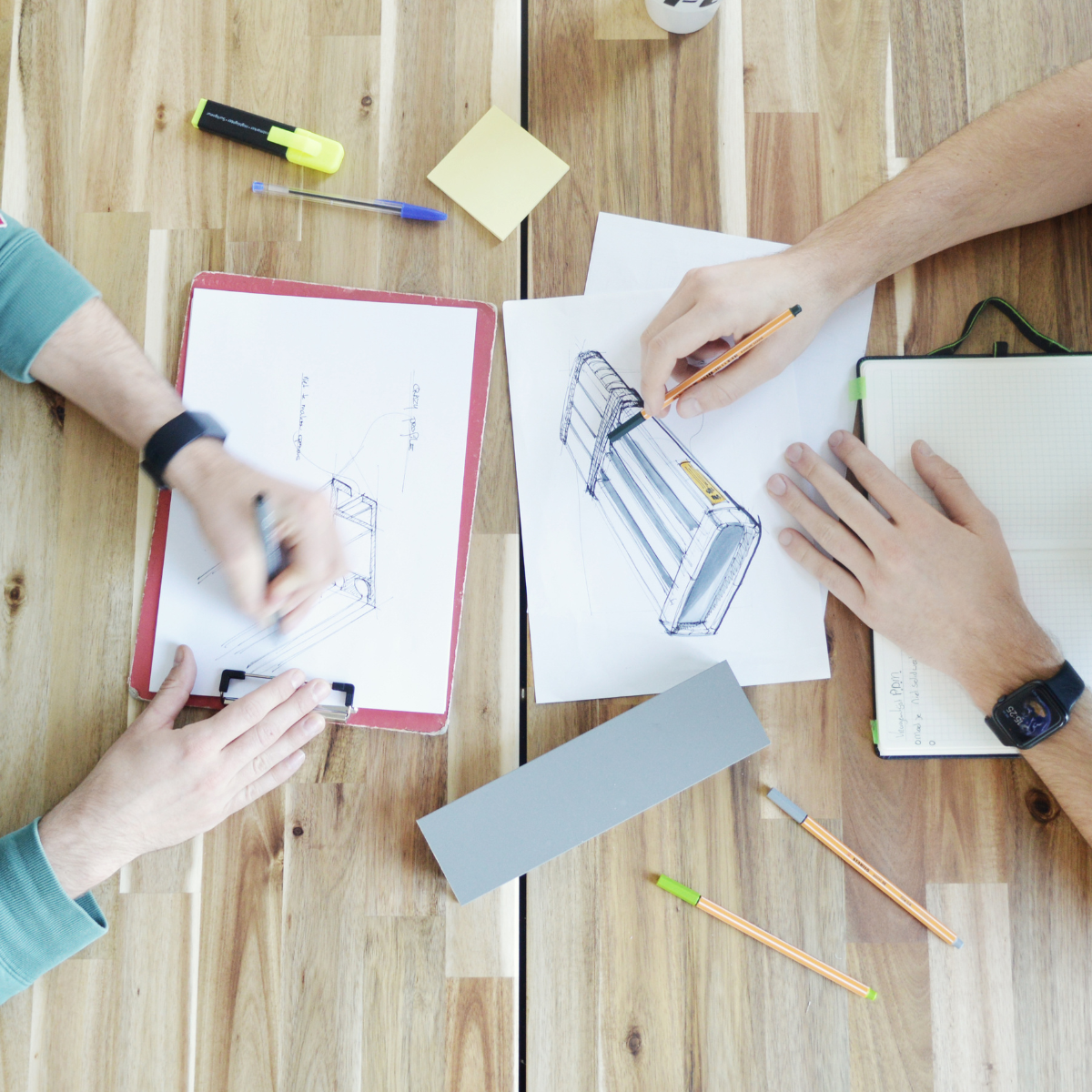

At BOAL Extrusion, we see that every application starts with the same question: what must this profile withstand in real‑world use? Not in abstract terms, but in concrete situations: wind load on a façade, water drainage in a greenhouse gutter, dimensional stability in prefab, cable routing in commercial construction. That’s why there are no brochures on the table during our discussions, but profiles, sketches and prototypes. These physical objects guide the conversation and show how aluminium makes the difference across diverse construction projects.

An open conversation

In a room filled with profiles, prototypes and test pieces, four specialists from BOAL Extrusion - Elke Tabak‑Keller, Ton Koldewijn and Eric Klever - join Senior Industrial Design Engineer Niels Schouten from Fabrique Invent at the table to share their experiences from real‑world construction. Not a formal interview, but an open conversation in which we hold profiles in our hands, discuss cross‑sections and walk through concrete building scenarios. Four people from the manufacturing industry who do not approach aluminium as a mere material choice, but as something you design, test, optimise and apply in real projects.

Alloys in the 6000 series form the backbone of circularity, sustainability and complexity - but why?

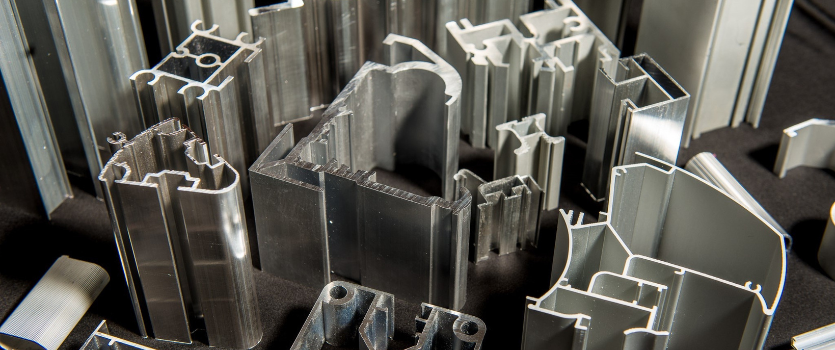

Ton slides a profile forward, with multiple chambers, ribs and integrated fastening points. “This is typical 6000 series,” he says. “Strong, formable and endlessly recyclable. That’s exactly why these alloys play such a major role in modern construction projects.” Elke nods. “Clients increasingly want to know how circular and sustainable their material is. And with aluminium from the 6000 series, you can genuinely demonstrate that. The material retains its quality, even after multiple life cycles.” Niels adds: “For us as designers, it’s the perfect combination. You can create complex geometries without compromising sustainability in the broadest sense of the word. That’s rare.”Eric smiles: “And the beauty is: circularity, sustainability and complexity don’t have to clash. With aluminium, they actually reinforce one another.”

"The 6000 series is the sweet spot: technically challenging, fully circular and high in quality and therefore highly sustainable."

Ton Koldewijn - Technical Support ManagerDesign freedom only has value when it’s manufacturable

As the conversation shifts toward design, Niels leans forward. “Design freedom is fantastic, but only when it’s manufacturable. A profile can be brilliant on paper, but if it can’t be extruded, it’s useless.” Ton smiles. “That’s where we come in. Sometimes a single added radius or a slightly different wall thickness is enough to make a design feasible.” Elke adds: “And that’s exactly why we want to be involved early. In residential and commercial construction, designers often want to integrate a lot: ventilation ducts, fastening points, cable channels. All of that is possible.” “Especially when you approach it smartly,” Niels from Fabrique Invent adds. Eric: “In prefab it’s even more extreme. There, manufacturability literally determines construction speed. A profile that comes out of the die right the first time saves days on the building site.”

Design freedom is not a goal in itself; it only becomes valuable when it is manufacturable.

Niels Schouten - Senior Industrial Design Engineer Fabrique InventLCA’s and EPD’s – the numbers behind sustainability

Elke slides an EPD forward. “These kinds of documents are becoming increasingly important. Especially in commercial and residential construction, where sustainability requirements are getting stricter.” Ton: “An LCA shows exactly where the impact lies: alloy, energy source, processing. Aluminium performs surprisingly well there, especially when you use recycled material such as BLEU by BOAL.” Niels: “For us, it has become a design tool. If a certain alloy emits 20% less CO₂, we incorporate that into the design. You can genuinely steer towards sustainability in the broadest sense of the word.” Eric: “And customers appreciate that. They want hard numbers, not marketing.”

Smart processing - fewer failure costs, faster installation

Ton picks up a profile with integrated punch holes. “This is where you prevent failure costs. Not on the construction site, but here, in the factory.” Eric: “In prefab and façade construction, that’s crucial. The more you solve upfront, the fewer risks you face during installation.” Elke: “And in residential and commercial construction, it’s all about speed. Smart processing means fewer tolerance errors, fewer manual steps, fewer delays.” Niels: “We increasingly design with the mindset: what can we already integrate in the extrusion or processing stage? That accelerates everything.”

Focus on construction, but why?

BOAL and Fabrique Invent have a clear sector focus: residential construction, commercial construction, façade construction, prefab and - in the case of BOAL Extrusion - even greenhouse construction. Why these five domains? And what makes extruded aluminium from BOAL Extrusion such a logical, or even indispensable, choice within them?

Residential construction

Let’s start with housing. What makes aluminium so relevant here?

Elke: “Residential construction is about comfort and appearance. Residents want light, space and a modern look. Aluminium makes that possible with slim profiles that support large glass surfaces without looking bulky. At the same time, thermal breaks allow you to achieve high insulation values. And the material is practically maintenance‑free, a huge advantage for both residents and developers.” Ton: “And don’t forget the lifespan. Aluminium lasts for decades without losing performance. That makes it a sustainable long‑term choice.”

Commercial construction

And what about commercial buildings? That’s a completely different world, right?

Eric: “True, but the requirements are similar: robust, reliable and flexible. Commercial construction demands large spans, integrated technical functions (think cable trays, ventilation ducts, fastening points) and a high level of fire safety and stability. Aluminium can deliver all of that. It’s lightweight yet strong. And you can integrate functions directly into the profile, reducing the number of separate components.” Ton: “That makes buildings not only more efficient, but also more future‑proof. You can adapt, expand or renovate more easily.”

Façade construction

Façade construction seems like an obvious sector for aluminium. What makes it such a perfect match?

Ton: “Façade builders want slim, clean and durable solutions. Aluminium is almost the natural choice. You get slender, strong profiles that carry large glass panes without compromising safety. The material is naturally corrosion‑resistant, which is essential for outdoor use. And in terms of finishing, anything is possible: anodising, powder coating, colours, textures - you name it.” Elke: “Aesthetic freedom is a real asset here. Architects can create exactly the look they envision.”

Prefab

Prefab is booming, what makes aluminium such an accelerator here?

Niels: “Prefab is all about predictability. Everything must fit, click, slide and assemble without surprises. Aluminium is lightweight, so you need less lifting capacity. It’s dimensionally stable, so components fit together perfectly. And you can integrate functions like fastening points, chambers, ribs, etc., reducing the number of separate parts.” Eric: “And that means faster construction, fewer failure costs and fewer risks on site. That’s exactly what prefab is about.”

Greenhouse construction

Finally, greenhouse construction - a sector where BOAL has an impressive track record. What makes aluminium so unique here?

Ton: “This is aluminium at its best: slim, strong, designed for maximum light transmission, smart and robust regardless of geographical challenges. Greenhouse construction demands maximum light and minimal shadow. Slim profiles are essential. Aluminium provides the strength for large spans while remaining light and elegant.” Elke: “Smart geometries prevent condensation. Droplets on crops can cause mould, something you absolutely want to avoid. By integrating separate drainage chambers into gutters, we enable growers to separate rainwater and condensation water intelligently. Crucial when you talk about sustainable water management in horticulture.” Eric: “Corrosion resistance is also a must. A greenhouse is a humid, dynamic environment. Aluminium stays stable for years.” Ton: “Greenhouse construction is a discipline of its own. You’re not just designing a structure - you’re designing a microclimate where everything revolves around light, air, water and temperature. Aluminium is practically applied physics here.”

"In greenhouse construction, aluminium is not just structure - it is light and water management."

Elke Tabak-Keller - Senior Account ManagerCollaboration as a success factor

The conversation ends the same way it began: with collaboration. Niels: “The reason our projects succeed is because we involve each other early. Design, material and production have to function as one.” Ton: “Extrusion is co‑creation. You can’t just pull a standard profile from a catalogue.” Elke: “The best moment is when a customer says: ‘We could never have made this without you.’” Eric: “And that’s exactly what BOAL stands for: thinking along, asking the right questions, optimising and innovating.”

Aluminium as a strategic building block

What stays with you after this energetic conversation is that aluminium isn’t a material you simply pick up and use. It’s a strategic choice that brings together design freedom, sustainability and manufacturability. In residential construction, commercial construction, façade engineering, prefab and greenhouse construction, aluminium truly makes the difference - provided you use it intelligently.

Facing a construction challenge? Or curious to understand what aluminium could mean for your project? These experts are ready to help you find the right solution. Go ahead and challenge them!

Read more

BOAL GROUP JOINS UN GLOBAL COMPACT SDG FLAG DAY

‘s-Gravenzande, The Netherlands, September 23rd 2022. Since the beginning of this year, the BOAL Group has joined the United Nations Global Compact in...

Read more

BOAL LAUNCHES CORPORATE VIDEO

Today, BOAL Group launched its new corporate video. The video clearly explains BOAL’s background, its purpose and its ambitious ESG-goals. Watch the v...

Read more

BOAL GROUP RATED #1 BY SUSTAINALYTICS ON ESG PERFORMANCE IN ITS CATEGORY

Naaldwijk, the Netherlands, june 9th 2022. BOAL's controlled environment agriculture (CEA) products play a pivotal role in the transition to reduce th...

Read more