Manufacturability and Design Freedom

What aluminium extrusion makes possible

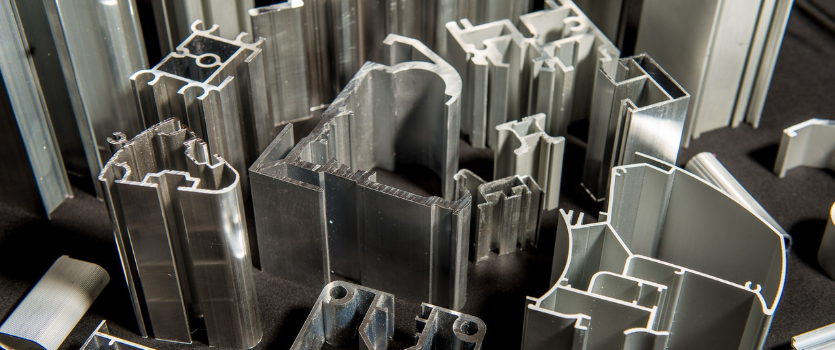

In the construction sector, design freedom is essential, but only when it goes hand in hand with manufacturability. Aluminium extrusion offers a unique combination of both. Thanks to the malleability of aluminium and the precision of the extrusion process, profiles can be designed to meet functional requirements, aesthetic preferences, and technical specifications with exact accuracy.

What makes extrusion so powerful?

Extrusion is a manufacturing technique in which aluminium is pressed through a die under high pressure. The result: a profile with a constant cross-section, accurate down to the millimetre. This process makes it possible to:

Create complex geometries: including chambers, ribs, snap-fit connections, and cable ducts.

Integrate functions into the profile: simplifying and speeding up assembly.

Optimise material efficiency: by designing intelligently with minimal wall thicknesses and targeted reinforcements.

For designers, this means greater freedom of form, fewer components, and a higher degree of integration.

Design freedom in practice

Aluminium extrusion gives designers the scope to develop profiles that seamlessly fit their application, from façade systems to technical enclosures. Thanks to the material’s freedom of form, modular and scalable solutions are possible, making it particularly suitable for prefabricated building concepts and repeatable systems. Here, aesthetics and functionality go hand in hand: clean lines, concealed fixings, and integrated features deliver both a premium appearance and practical added value.

This design freedom, however, is not without responsibility. It requires technical coordination during the design phase, where manufacturability, tolerances, and processing options are carefully considered. Only then can the full potential of aluminium extrusion be realised, in both design and execution.

Manufacturability is valuable

A good design is only valuable if it can be manufactured. That is why it is essential to take into account, already in the design phase:

Extrusion-related limitations: such as minimum wall thicknesses, radii, and die complexity.

Processing options: such as sawing, punching, milling, and surface treatment.

Assembly and installation: how the profile behaves during the building process.

By integrating these factors at an early stage, a profile emerges that is not only well designed but also efficiently produced and applied.

From Concept to Profile

Challenge us to turn your design freedom into a manufacturable profile – together we ensure aesthetics, functionality, and efficiency go hand in hand.

Designing with aluminium – A strategic choice

Aluminium extrusion gives designers and builders the opportunity to think beyond standard solutions. It is a technique that encourages customisation, integration, and innovation. Provided that design and production go hand in hand. In a sector increasingly demanding speed, circularity, and technical precision, this is not a luxury, but a necessity.

Read more

BOAL GROUP JOINS UN GLOBAL COMPACT SDG FLAG DAY

‘s-Gravenzande, The Netherlands, September 23rd 2022. Since the beginning of this year, the BOAL Group has joined the United Nations Global Compact in...

Read more

BOAL LAUNCHES CORPORATE VIDEO

Today, BOAL Group launched its new corporate video. The video clearly explains BOAL’s background, its purpose and its ambitious ESG-goals. Watch the v...

Read more

BOAL GROUP RATED #1 BY SUSTAINALYTICS ON ESG PERFORMANCE IN ITS CATEGORY

Naaldwijk, the Netherlands, june 9th 2022. BOAL's controlled environment agriculture (CEA) products play a pivotal role in the transition to reduce th...

Read more